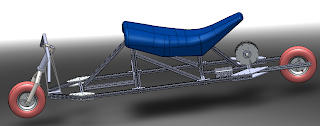

It kind of like a minibike..ish. Its been called a skate board crossed with a scooter among various other things, but nothing seems to describe it right. Either way its coming along and its about time for the post of the project. To start off here's the (partially incomplete because I'm lazy) cad model of the project:

Despite being incomplete the vehicle is pretty much the same shape as the cad model. However there were several changes to the structure of the vehicle that were just done on the fly. Namely all the additional supports besides the vertical posts holding the seat up. But I'll get to that in the next post.

In retrospect it was a bad decision to use 20mm framing for this, not because it is skinny but because the 20mm 80/20 on mcmaster carr uses M5 nuts/screws and its difficult to find M5 tabbed weld nuts of the proper dimensions (at least in quantities less than several thousand) which forces you to buy the expensive proprietary ones actually meant for the framing. If it had been made with 25 or 30 mm extrusion the frame would have been quite heavier not to mention more expensive but the price difference might have been compensated for if I was to using generic nuts.

Time to go over the construction of the vehicle:

|

| Partially machined tubes |

Machined tubes fit being fit together and the welded fork.

|

| Steel plugs inserted into fork |

The plugs were then welded in place then flats were milled onto the sides and a 1/2" bit was drilled through for the shaft which is also 1/2".

|

| Fork awkwardly clamped down ready to get its flats |

Note: the welds were ground down because they looked ugly. The welds seem solid though, after attempting to break them several times unsuccessfully, they're expected to be strong enough to hold a mildly obese person.

|

| plugs with holes going though fork |

A chunk of steel was turned down to act as the fork crown and support the bottom bearing of the headset and the bearings were press fit into the head tube.

|

| Ghetto step welded on now the Y of the fork is a complete mass of ground down weldedness |

Next step was to make a method of attaching the head tube to the rest of the frame.

I kinda winged it and welded some 1/8" steel U-channel to make an attachmenty thingma dig, it takes x2 M8 bolts in the bottom to hold it on the front brace of the rest of the frame. Here is the head set/fork mounted on the frame base:

It was a giant floppy mass at this point but I get into the rest of the structural details later.

Those little orange wheels were obtained from harbor freight for a disturbingly cheap price of like $8.50 a piece. They came with a matching pair of disturbingly crappy bearings; after watching someone else using the same wheel destroy their bearings, I decided it would be best to preemptively swap them out for a better set.

The old bearings were removed and a spacer was placed in the center of the wheel that would hold a bearing on either side. The new bearings were then press fit in up to their retaining rings, but the spacer was over sized slightly to make sure that it would contact both inner bearing races.

|

| Turning down one of the spacers. |

|

| Spacer next to bearing |

|

| Bearing on spacer |

|

| Spacer and bearing in hub of wheel |

The hub spacer forms a bridge between the two hub bearings effectively making a solid column, making sure that both of the inner bearing races are supported at the same time.

The next step was to actually get handles bars on the bike by making the bike stem. In the course of this the main thing learned was that the bike stem was not called the 'handle bar holder'.

|

| Started with a large chunk of aluminum |

|

| Drilled some holes for a flexture clamp to hold the handle bars and reamed a larger hole to take the top of the bike fork |

|

| Bike with temporary handle bars installed... it also grew a seat and a motor in this picture but we can talk about that later. |

Yay it's finally a rolling frame. But it has no support structure and I would not bet it on holding any one with that skinny 20mm 80/20 frame. This part actually posed some annoying requirements since 80/20 framing really doesn't do angles well unless you make your own brackets for it. It probably would have taken less time to learn to weld aluminum and put the frame together at this point each joint has too many nuts and screws it both seems annoying inelegant and pain in the ass to make. That being said this post

feels really long so talking about how this flat floppy frame was made structural will be talked about in part II of this post.

No comments:

Post a Comment